We are SAE 17-4PH Stainless welded pipe,17-4 PH stainless steel plates supplier

17-4 ph vs 316,17-4ph iso,17-4 ph stainless steel machinability,17-4ph equivalent,17-4 ph vs 304,17-4 vs 17 4 ph,17-4ph flat bar,17-4 ph welded pipes,17-4 ph pump shaft,17-4 ph stainless steel price,17-4 ph maximum temperature,17-4 ph fatigue properties, 17-4PH forge parts, 17-4PH round bar, 17-4PH SQ bar, 17-4PH SQ pipes

Ryin stainless factory produce 17-4PH Stainless welded pipe and 17-4 PH Stainless steel plates,17-4PH forge pieces,17-4PH machined parts.

SAE 17-4PH Stainless steel material supplier

SAE 17-4PH Stainless steel material supplier

What is 17-4 PH Stainless steel grade?

17-4PH stainless steel material (We usual call them SAE Type 630 stainless steel or simply 17-4; We also call UNS 17400) is a grade of martensitic precipitation hardened stainless steel. It contains approximately 15–17.5% chromium and 3–5% nickel, as well as 3–5% copper.

The name comes from the chemical makeup which is approximately 17% chromium and 4% nickel.

17-4PH alloy is a stainless steel with precipitation, quenching water, martensite, and this grade has high strength, hardness and corrosion resistance.

After heat treatment, the mechanical properties of the product are more perfect, and it can reach compressive strength up to 1100-1300 mpa (160-190 ksi).

This grade cannot be used at temperatures above 300 (570F) or at very low temperatures. It has good corrosion resistance to the atmosphere and dilute acids or salts.

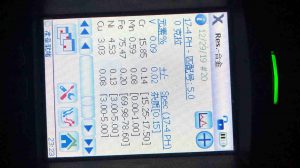

What is 17-4PH chemical composition?

| 17-4PH Stainless steel chemical composition % |

| 17-4PH |

C |

Si |

Mn |

Cr |

Ni |

Cu |

| 0.07 |

1.0 |

1.0 |

15.5-17.5 |

3-5 |

3-5 |

| Nb |

P |

S |

|

|

|

| 0.15-0.45 |

0.035 |

0.035 |

|

|

|

SAE 17-4PH Stainless Properties:

17-4 be heat treated to high levels of strength and hardness and features corrosion resistance and machinability comparable to austenitic 304 stainless. Being martensitic, 17-4 is magnetic.

when heat treated to condition H900,17-4PH hardened up to approximately 44 Rc.

Overaging (aging beyond the peak strength condition) improves resistance to stress corrosion cracking.

SAE 17-4PH Stainless applications:

Type 17-4 PH stainless steel has applications in industries like paper, petrochemical, aerospace and food processing Aerospace (turbine blades), Mechanical components, Nuclear waste barrel. It is widely used in various general metalwork applications.

What is PH meaning at 17-4PH stainless steel?

The precipitation hardening (PH) stainless steels are a family of corrosion resistant alloys

They are heat treated to provide tensile strengths of 850MPa to 1700MPa and yield strengths of 520MPA to over 1500MPa.

What is the difference between 17-4 and 17-4ph?

Type 17-4 PH provides an outstanding combination of high strength, good corrosion resistance, and good mechanical properties at temperatures up to 600°F (316°C). 17-4 PH has slightly more Ferrite than other PH grades, making it a bit more magnetic. 17-4 PH provides toughness in both base metals and welds.

If any requirement for 17-4PH stainless steel plate, round bar,17-4 PH seamless pipe and 17-4ph stainless welded pipes, please feel free to contact us.

People Also Search the following:

SAE 17-4 ph round bar vs 316,17-4 ph stainless steel machinability,17-4 h900 matweb,astm a693,s17400 nace,uns s17400 aisi 630,how to heat treat 17-4 stainless,ati 17-4,sae ams 2759/3,17-4 ph stainless steel price,uns s17400,17-4ph young’s modulus,15-5 ph,wrought 17-4ph,nitriding 17-4 ph stainless steel,17-7 stainless steel,aisi 630 standard,asme sa 564 type 630,17-4 ph stainless steel equivalent,astm a693 grade 630,17-4 h1150d,h900 rockwell hardness,h1025 spec,17-4 stainless steel flat bar,astm a564 free pdf,ams 5643,aisi 630,uns s17400 vs ss316,17 4ph density kg m3,15-5 ph chemical composition,17-4 max operating temperature,what is 17-4ph condition a,17-4 ph round bar,17-4ph square bar,17-4 stainless steel tube,347 flat bar.